Ansys Motor-CAD

Motor-CAD

Integrated Multiphysics Analysis Software for Electric Motor Design

Motor-CAD is the world-leading dedicated electric motor design software for multiphysics simulation of electrical machines across the full torque-speed range.

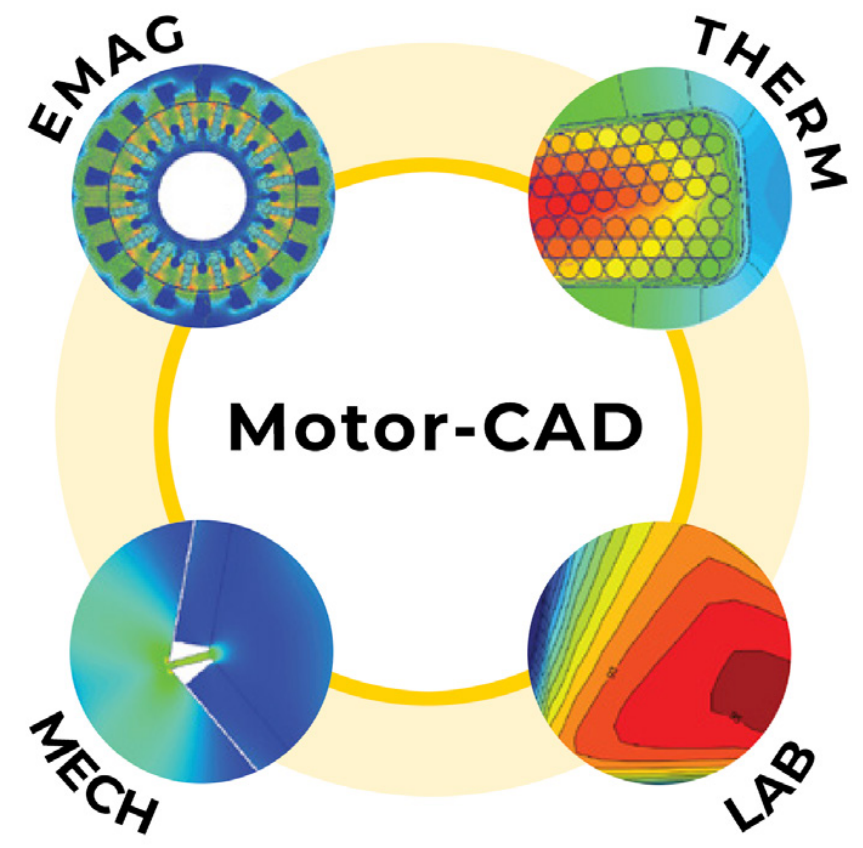

Evaluate motor topologies and concepts across the full operating range and produce designs that are optimized for size, performance and efficiency. Motor- CAD software’s four integrated modules — EMag, Therm, Lab and Mech — perform multiphysics calculations quickly and iteratively, so you can get from concept to final design in less time.

With decreasing development cycles, motor designers need to make design decisions quickly, and with certainty that they will not face problems down the line. Fast calculations and streamlined data input processes leave time for Motor-CAD users to explore more motor topologies and fully assess the impact of advanced loss effects in the initial stages of a design.

Motor-CAD software’s intuitive, template-based setup and embedded multiphysics expertise simplifies the design process and reduces reliance on multiple teams for specific electromagnetic, thermal or mechanical experience — so motor designers can keep more control over their designs.

Motor-CAD: Integrated Multiphysics Design Tool

EMag | Electromagnetic performance predictions

Uses a combination of a 2D finite element (FE) environment and analytical algorithms for fast calculation of electromagnetic performance. Optimize designs easily with our extensive range of parameterized templates and geometries.

Therm | Thermal performance predictions and advanced cooling system design

This is the industry-standard tool for thermal analysis of electric machines, with over 20 years of successful use.

Calculate the temperature of motor components in steady-state and transient operating conditions and accurately model thermal behavior within seconds of calculation.

Lab | Efficiency mapping and performance across a duty cycle

Enables rapid and accurate analysis of any electric machine design over the full operating envelope.

Carry out efficiency mapping and drive cycle analysis within minutes.

Mech | Mechanical analysis

Uses a 2D -based solution in Motor-CAD to analyze stress and displacement in rotors during operation.

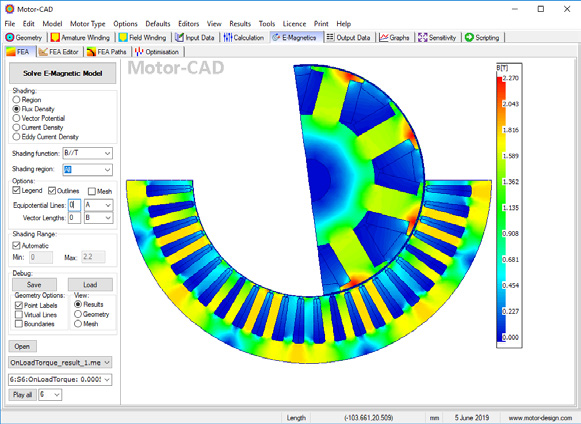

Motor-CAD Emag

Combined 2D finite element environment and analytical algorithms for fast calculation of electromagnetic performance.

Quickly perform a range of electromagnetic performance tests on prototype designs with Motor-CAD EMag, including calculation of torque, power, losses, voltages, currents, inductances, flux linkages and forces. Input and optimize designs easily with the module’s extensive range of parameterized templates and geometries.

Key Features

- Provides an extensive range of parameterized templates and geometries.

- Automatically sets up calculations for different performance tests.

- Enables calculation of torque, power, losses, voltages, currents, inductances, flux linkages and forces.

- Powered by embedded 2D transient or magnetostatic solvers with meshing and boundary conditions automatically set up.

- Enables advanced calculations, such as eddy current in magnets, or induction machine rotor bars and calculation of AC winding losses.

- Offers F and scriptable geometries, custom current waveforms and multi-slice rotor skewing.

- Combined 2D finite element and analytical modelling approach means designs can be input and calculated in minutes, enabling users to account for complex electromagnetic effects early in the design process.

- Can integrate with Motor-CAD Therm to solve thermal calculations iteratively.

- Links to ANSYS Maxwell for detailed analysis.

Workflow

STEP 1 | DEFINE YOUR MOTOR

Input Geometry

- Input geometry using the EMag parameterized template editor, where parameters —such as number of slots, number of poles and tooth width — can be specified.

- View and modify the geometry from a radial and axial perspective, draw the 3D geometry and easily export to other CAD packages.

Specify Winding

- Lay out coils using the EMag winding editor. Specify a custom winding pattern or allow Emag to automatically generate a winding pattern based on the specified number of phases, turns coil, coil pitch and layers.

- View the cross section of conductors in the slots.

- Define wires by slot fill factor or by wire dimensions, with an option to specify rectangular wire.

Input Materials Data

- Choose materials from our comprehensive materials database or specify your own material properties, such as B-H curves.

STEP 2 | CALCULATE RESULTS

- With the motor defined, choose from a range of performance tests, such as Back EMF, Cogging Torque and On Load Torque for BPM machines, or Single Load Point and Standard Tests (Locked Rotor, Synchronous Speed) for induction machines.

- Automatically mesh and handle boundary conditions and symmetry — you do not need indepth knowledge of numerical simulation techniques to get highly accurate results.

- Couple with the Motor-CAD Therm module to solve thermal calculations iteratively.

- Export complete transient Maxwell design for detailed FE simulations.

STEP 3 | GENERATE OUTPUTS

- The EMag output tab displays numerical data calculated from the solution, including voltages, inductances, torque ripple percentage, motor constants, short-circuit current and power factor.

- Loss components can also be analyzed, including DC and AC copper loss, magnet loss and iron loss.

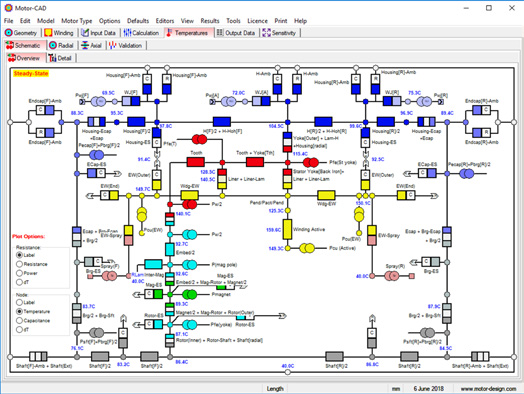

Motor-CAD Therm

The Motor-CAD Therm module is the industry-standard tool for thermal analysis of electric machines.

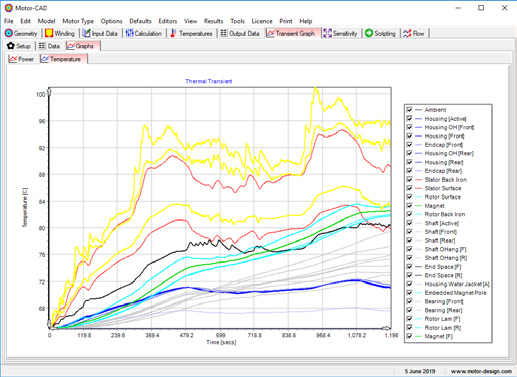

Motor-CAD Therm enables designers to calculate the temperature of the motor components in steady-state and transient operating conditions for accurate modeling of thermal behavior within seconds of calculation.

Understanding the main heat transfer paths gives motor designers opportunities to significantly improve motor efficiency power output and make design decisions with confidence.

Key Features

- Calculates the temperature of the motor components in steady-state and transient operating conditions.

- Generates thermal and flow network automatically.

- Includes radial and axial heat transfer in a 3D network.

- Provides detailed visualization and calculation of the slot cross section.

- Produces all calculations with , and empirical correlations.

- Assists in selecting appropriate manufacturing factors with experience built into the software.

- Enables accurate modeling of thermal behavior within seconds of calculation.

Workflow

STEP 1 | SPECIFY COOLING SYSTEM

- Motor-CAD Therm lets you select cooling types, such as a water jacket or fan cooling method.

- You can define housing dimensions such as channel or fin size, and select cooling-type dependent inputs, such as flow rate and fluid properties.

STEP 2 | SET THERMAL PROPERTIES

- Motor-CAD Therm lets you select the thermal properties for the impregnation, slot liner and housing materials.

- You can then choose the manufacturing factors, such as lamination-to-housing interface gap or impregnation goodness.

STEP 3 | CALCULATE TERATURES

- When you click ‘Solve’, Motor-CAD Therm automatically generates an equivalent thermal network, which can be used to calculate thermal performance.

- Calculate steady-state temperature, as well as the transient temperature of the motor across a duty cycle.

- Import or iteratively solve losses with the Motor- CAD EMag and Lab modules.

STEP 4 | GENERATE OUTPUTS

- Output data gives users extensive information about the thermal model, including temperatures, the axial temperature distribution, losses, heat transfer coefficients, thermal resistances and more.

Motor-CAD Lab

Efficiency mapping and performance across a drive cycle.

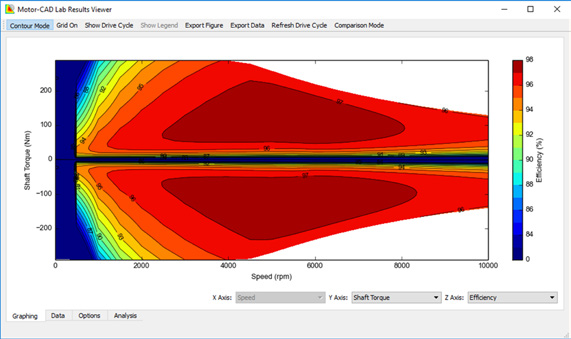

The Motor-CAD Lab module has been developed to enable rapid and accurate analysis of any electric machine design over the full operating envelope. It couples to both the EMag and Therm modules and provides outputs such as efficiency maps and torque/speed characteristics.

Key Features

- Generates efficiency and loss maps.

- Calculates the peak torque/speed characteristic.

- Calculates the continuous (thermally constrained) torque/speed characteristics.

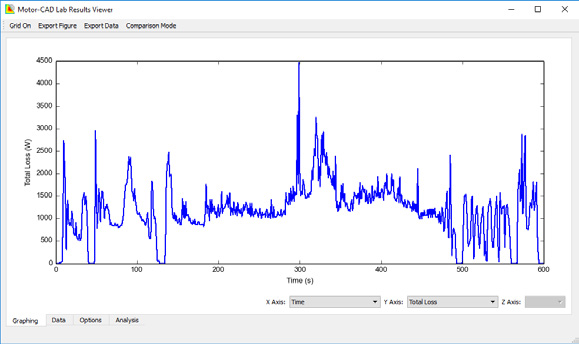

- Analyzes performance over complex driving cycles.

- Uses maximum torque/amp and maximum efficiency control strategies.

Workflow

STEP 1 | BUILD THE MODEL

Build the saturation and loss model using the electromagnetic solver. This process builds a set of response surfaces in a few minutes, which are then saved internally.

STEP 2 | CALCULATE RESULTS

Calculating efficiency maps and torque/speed curves

- Specify inputs, such as DC link voltage, control strategy, maximum inverter current and maximum modulation depth.

- Complete the model build and generate outputs such as efficiency maps and peak torque/speed curves within seconds.

Calculating Thermal Envelopes and Drive Cycles

- The Motor-CAD Lab and Therm modules can be iteratively solved to provide outputs, such as the continuous torque/speed envelope, which calculates the maximum continuous output torque

across the speed range within a set of winding and rotor temperature limits.

- The Lab module also calculates the losses and temperature rise of a prototype design over a drive cycle.

STEP 3 | GENERATE OUTPUTS

- Users can plot, visualize and study a large range of different outputs such as power/speed characteristics, loss maps, efficiency maps, drive cycle efficiency and thermal maps.

- Results can be exported in various standard data formats.

- Motor-CAD software can be fully automated and controlled through scripting tools such as MATLAB® and Excel® as well as a range of other third-party optimization solutions.

Motor-CAD Mech

2D -based solution in Motor-CAD to analyze stress and displacement in rotors during operation.

Analyze the mechanical stress in rotors using the Motor-CAD Mechanical Model.

Key Features

- Calculates stress and displacement in rotors during operation.

- Optimizes the design of the rotor to maximize electromagnetic performance within the mechanical limits.

- Provides a 2D FE solver with automatic meshing.

- Is intelligent to ensure correct problem configuration.

- Provides very fast solutions — typically within a few seconds.

Workflow

STEP 1 DEFINE THE MOTOR ROTOR

- Rotor geometry is input using the Mech parameterized template editor, where basic parameters — such as number of poles and inner and outer diameters — can be specified.

- For M machines, additional fundamental parameters, such as magnet clearance, flux barriers, magnet posts and rotor bridges, can be adjusted.

- Rotor materials can be chosen from Motor-CAD’s material database or you can specify your own material properties.

- Young’s modulus, density and Poisson’s ratio are defined and utilized in the mechanical stress analysis. The characteristic yield strength and tensile strength can also be input and used as references for future design decision-making.

STEP 2 | DEFINE THE SETTINGS

- With the motor rotor defined, you can adjust the mesh in high-stress regions to get more accurate results. Motor-CAD software’s solver automatically handles boundary conditions and rotor symmetry to speed up the calculation.

- Rotational speed is input and used by the solver to calculate the centrifugal pressure into the rotor structure.

- You can decide to include magnets (BPM) or bars (IM) into the rotor core to evaluate the resulting impact on the rotor mechanical strength.

- For M machines, you can soften the contact between the magnets and the rotor to account for the adhesion between the magnet and lamination, to ensure realistic results.

STEP 3 | GENERATE OUTPUTS

- Once the problem is solved, you can visualize results, such as directional displacements and Von-Mises stress distributions, within the rotor radial cross section.

- The Mech output tab displays numerical data calculated from the solution, including averaged Von-Mises stress, maximum Von-Mises stress and safety ratio with respect to the rotor yield strength.

- Motor-CAD has built-in sensitivity analysis to perform a range of what-if analyses on design variants.

Detailed Modeling Analysis and Validation

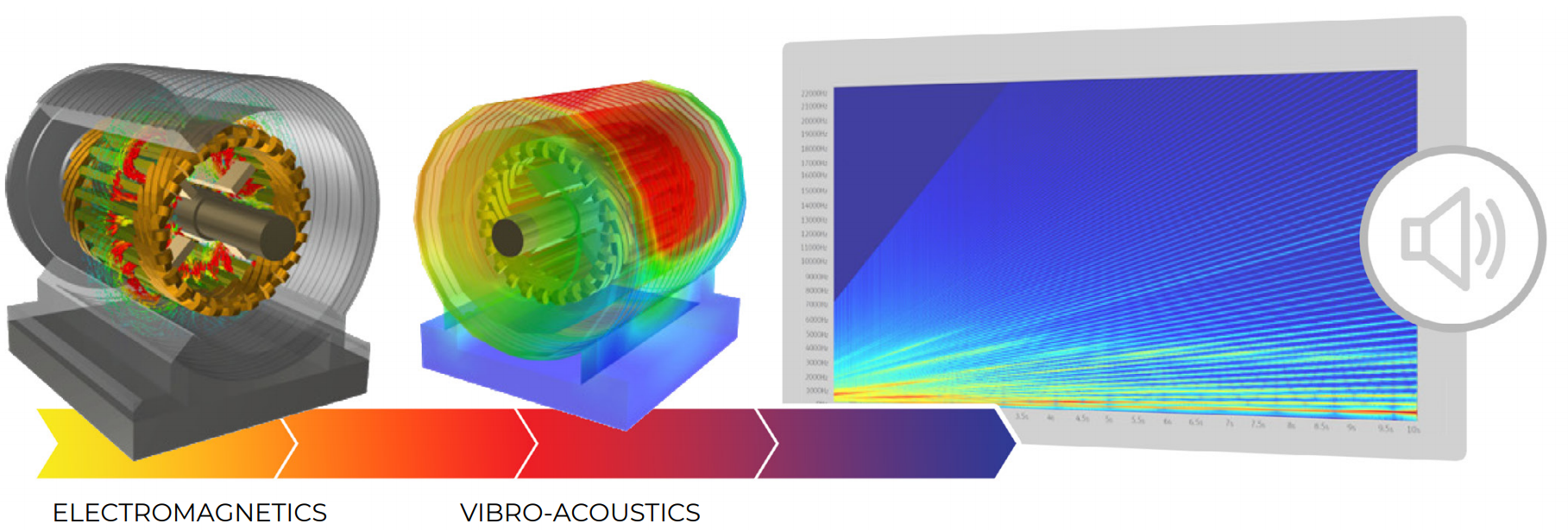

Motor-CAD is linked to Maxwell to perform detailed design and validation after the initial design. Maxwell can execute rigorous 2D and 3D performance calculations of the machine, including the motion-induced physics caused by linear translational and rotational motion, advanced hysteresis analysis, demagnetization of permanent magnets and other critical electromagnetic machine parameters.

Maxwell is integrated into ANSYS Electronics Desktop, where it can share the same CAD source and can be coupled to ANSYS Mechanical, ANSYS Fluent or ANSYS Icepak. Mechanical’s stress, thermal, and acoustic solvers provide important multiphysics capabilities required for a detailed analysis of the electric machine. Losses calculated by Maxwell can be used as inputs to the thermal or solver to calculate the temperature distribution of the machine and evaluate cooling strategies.

Electromagnetic forces and torque calculated in Maxwell are used as inputs to the stress solver to analyze deformations and further assess potential vibrations. The ability to perform an in depth multiphysics analysis with ANSYS’ powerful solvers truly sets the ANSYS Motor-CAD apart from the competition.

- Làm ơn ghi rõ "Nguồn Advantech .,Jsc" hoặc "Theo www.advantech.vn" nếu bạn muốn phổ biến thông tin này