Simulation Solution for Noise analysis of gear transmission system

Simulation Solution for Noise analysis of gear transmission system

In daily life, we might have encountered many devices that cause noises during operations such as washing machines, pumps, motorcycles, air conditioners, airplanes, etc. Beside the useful features, the noises generated from the devices make the users feel uncomfortable.

In engineering, noise problems are carefully studied and calculated to enhance users’ experience. (Noise, Vibration, Harshness) is a case worth to be studied including the characteristics of devices’ noise and vibration.

|

Figure 1: NASA researchers at Glenn Research Center conducting tests on aircraft engine noise in 1967 |

To get the good results, the products will have to go through an important step which is experimentation. In addition to ensure that the features of the product will work well, a factor that need to be tested is the noise generated during operations. The results will be used to improve the product and enhance users’ experience.

However, this experimental method has limitations in the product designing process such as time-consuming, costly, and repeatedly testing after each change in design, etc. They might affect the economic efficiency as well as the competitiveness of the new product launch time.

To solve these problems, design engineers could use engineering simulation software to determine noise effects. From there, they could provide the appropriate designs before going into prototype manufacturing and practical testing.

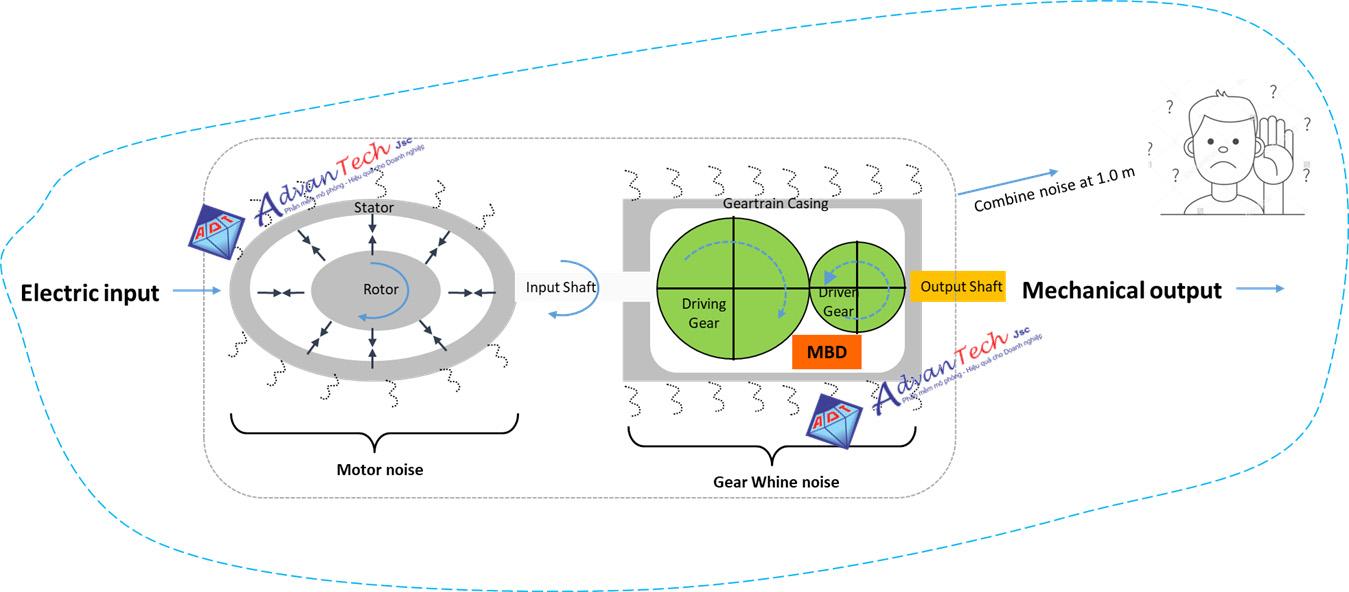

Considering the problem of calculating the noise generated during the working of a gearbox. The main parts of a gearbox include: Counter shaft, main shafts, gears and bearings.

In the process of working, there is a transmission/collision between gears and friction in bearings or vibration of the gearbox... These are all the sources of noise and have the direct impacts on operators as well as the surrounding environment.

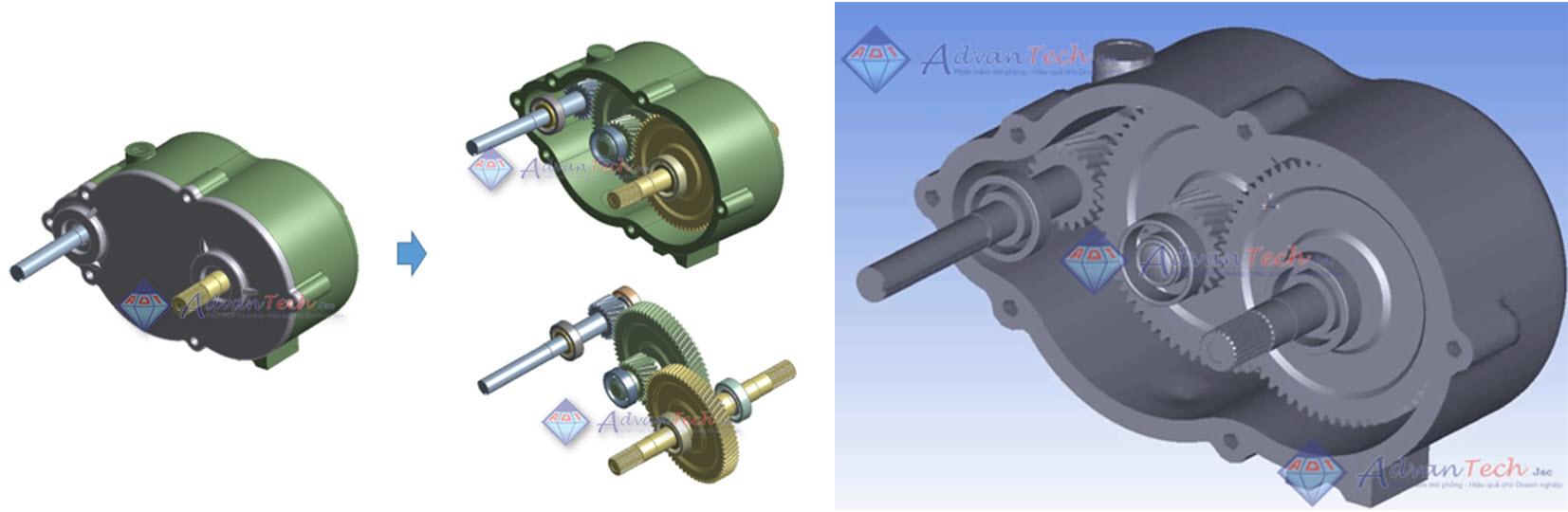

The software allows engineers to easily build 3D models from ideas and conduct virtual tests:

Figure 2: Gearbox model and transmission between axes

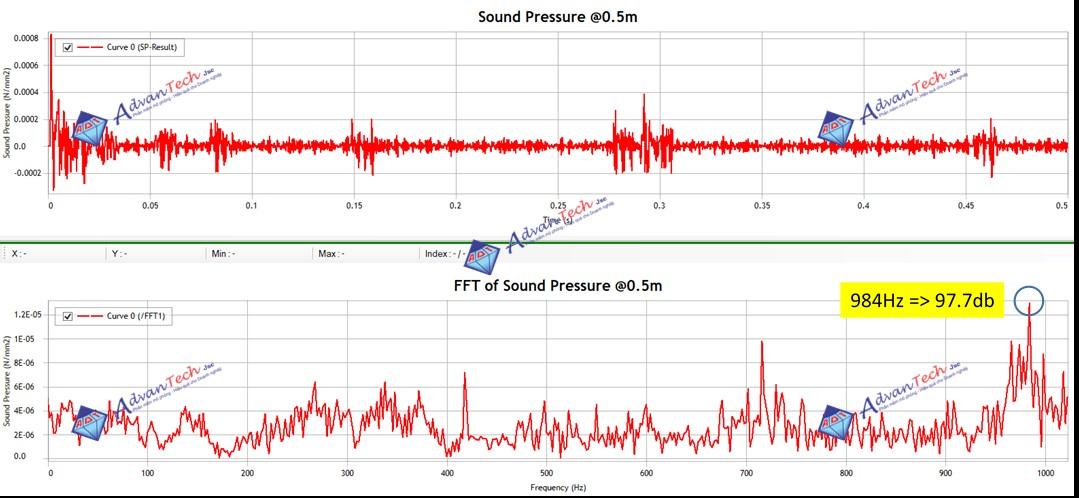

During work, noise spreads to the surrounding environment while the magnitude at each location is different. For experimentation, the points of noise survey should be set up in advance. This causes restrictions on the number of measurable results. With simulation software, users can exploit the results at various locations.

Figure 3: Result of sound pressure and sound intensity

Noise analysis results help engineers come up with different improvement/innovation options to produce the best products. Furthermore, engineers can also provide working conditions or work areas that are safe for users.

problem can also be applied for many objects such as:

- Noise in cars

- Audio equipment

- Study in the noise of the engines

- Aircraft engine

- Washing machines

- …

Source of geometric models: https://grabcad.com/library/atv-gearbox-1

To get more information on this analysis or related simulation solutions, please feel free to contact us: info@advantech.vn

- Làm ơn ghi rõ "Nguồn Advantech .,Jsc" hoặc "Theo www.advantech.vn" nếu bạn muốn phổ biến thông tin này